Experience

Wind Turbine Technician

Global Wind Service | Istanbul, TURKEY

- VESTAS Soganli Ext - 11 x V150-4.5MW

Reserve Officer

Turkish Air Force

- Completed one year of compulsory military service.

E&I Quality Control Engineer

SAM Mekanik Enerji SOCAR Türkiye Tesisi | Izmir, TURKEY

- Developed and managed critical quality documentation, including NFI, MAR, MRIR, FQD, and ITP.

- Conducted technical tests such as megger tests, loop tests, functional tests, and control valve testing.

- Utilized Equipment and Tools: HART Communicators, Fluke testers, and various hand tools.

- Performed technical tasks during the commissioning of 15+ 400V power panels.

Computer Vision R&D Intern Engineer

EGEROBOT | Izmir, TURKEY

- Designed and implemented a chemical container cover detection program that analyzed over 500 images, providing "open", "closed", and "gap" status indicators with 95 accuracy, contributing to safety measures.

- Enhanced dataset stability by applying cutting-edge data augmentation methods, such as image distortion and pixel-level manipulation, resulting in a 50% reduction in model overfitting and improved generalization performance.

- Led a team in implementing a new safety protocol, resulting in a 30% decrease in workplace incidents.

Intern Engineer

WEROVER | Izmir, TURKEY

- Gained practical experience with communication protocols, enhancing skills relevant to industrial instrumentation and control systems.

- Contributed to the successful progress of projects, helping to ensure that delivery timelines were met as planned.

- Manufactured PCBs using CNC machines, showcasing attention to detail and precision relevant to technical tasks.

Intern Project Engineer

Tüpraş Oil and Gas Refinery | Izmir, TURKEY

- Designed and led bioethanol production project from switchgrass, implementing sustainable techniques and collaborating with students from different engineering disciplines.

- Acquired comprehensive knowledge of refinery processes, including instrumentation, control systems, and interpretation of P&ID drawings.

Intern Engineer

Aliağa Municipality, Department of Public Works, Electrical Unit | Izmir, TURKEY

- Performed electrical maintenance and troubleshooting for 50+ streetlight systems across Aliağa district.

- Diagnosed and resolved electrical failures in streetlight systems, including fuse replacements and timer relay installations.

- Performed all phases of on-site electrical installations, including cable pulling, termination connections, and pole assembly.

Projects

Petkim Electrical Installation Improvement Projects

Spearheaded the overhaul of electrical installations across LDPE Plant, WDU Building, and PP Plant, enhancing overall system efficiency by 30%.

- 206-2020-1233 – AYPE Plant Living Areas Electrical Distribution Panel Renewal

- 207-2020-886 – PP Plant Operations Building Electrical Installation Renewal

- 275-2020-713 – Waste Disposal Unit Building Electrical Installation Panels Design & Installation Renewal

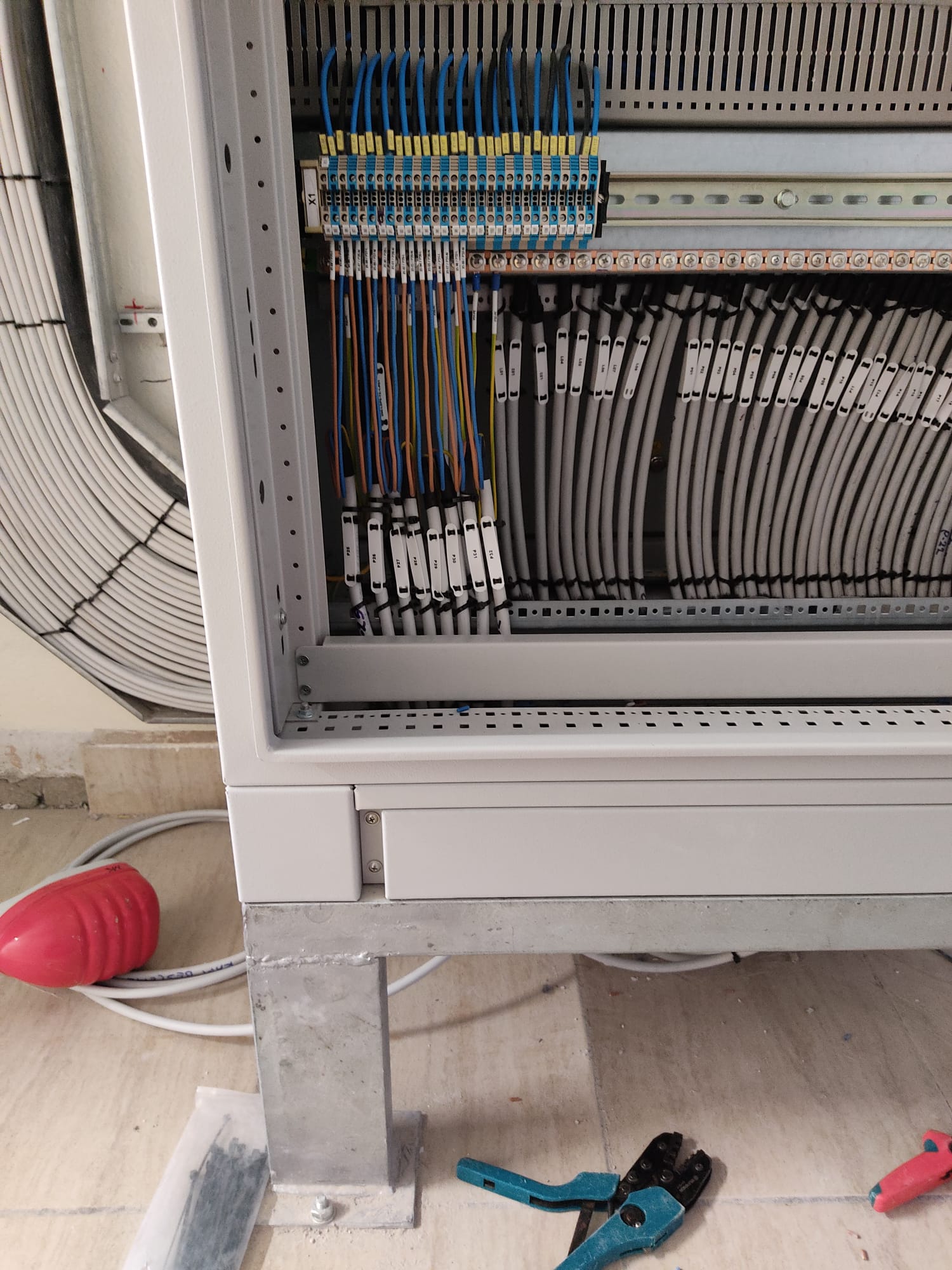

Star Rafinerisi Elektrik Tesisat İyileştirme – 400V Nötrlü Saha Priz Panolarının Yenilenmesi

SOCAR Türkiye STAR Rafinerisi sahasında 400V nötrlü saha priz panolarının yenilenmesi, kalite testlerinin yürütülmesi ve dokümantasyon süreçlerinin yönetimi gerçekleştirilmiştir.

- 12'den fazla pano sahaya yerleştirilerek kurulum ve devreye alma işlemleri tamamlandı.

- Kablo süreklilik testleri, izolasyon ölçümleri ve sigorta testleri başarıyla yapıldı.

- Tüm kalite kontrol dokümanları (ITP, MRIR, FQD vb.) hazırlanarak dokümantasyon süreçleri tamamlandı.

- Walkdown öncesinde sahada aktif görev alınıp punch list düzenlemeleri gerçekleştirildi.

- Müşteri memnuniyetini sağlamak amacıyla saha teslimi öncesi kalite doğrulama ve son kontroller yapıldı.

AI-Assisted Chemical Boiler Cover Detection

Developed an AI system for detecting the status of chemical boiler covers. The system can detect whether the cover is 'Open', 'Closed', or 'Cap' for safety purposes.

Education

Adnan Menderes University

Bachelor of Electrical and Electronic Engineering (100% English)

Certifications

Technical Skills

Software & Tools

- AutoCAD

- MATLAB

- HART Communicators

- Fluke 1507, 710, 175

- Microsoft Office, Project, Asana

Languages and Soft Skills

- English (Advanced, B2)

- Communication

- Teamwork

- Leadership

- Self-learning